Quality Assurance

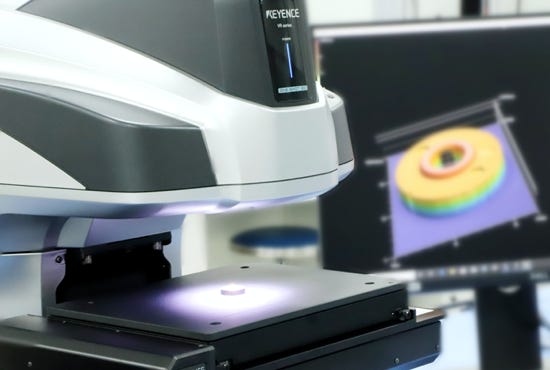

Measuring the shape and roughness of the product, from the whole to the local details, can be measured by one device, and the measurement range is 5 times that of the previous one. Equipped with "automatic processing and setting function" to eliminate human measurement errors.

High-density scanning points, high reliability and high repeatability measurement results can be obtained; probe connection method and length range are widely applicable; ceramic parts and long bearing seat ensure accuracy and reproducibility; small base and backpack control The cabinet saves more space.

Using 128*128 matrix array Hall probes, the surface scanning of the magnetic steel quickly shows the magnetic distribution of the surface. The software is compiled based on Python, and the analysis results are more intuitive and convenient.

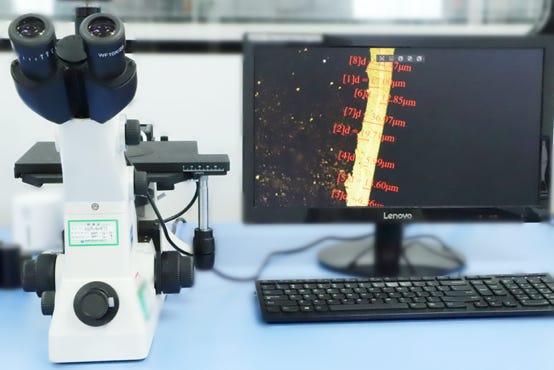

Equipped with large-field eyepieces and long-distance plan achromatic objectives, no cover glass, large and clear field of view. With locking and limiting device, coarse movement tightness, fine movement scale value and halogen lamp can be adjusted. It can switch between normal observation and polarized light observation, and can perform light-transmitting photography.

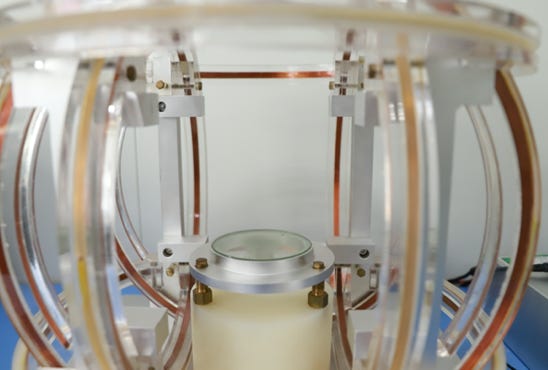

The three-dimensional Helmholtz coil is connected to the three-component fluxmeter, the magnet is placed on the sample stage, and the magnetic flux value, magnetic moment and angle values of the three components can be obtained through special software. The software can display measurement data and perform statistical analysis on it, and display MX, MY, MZ, M and magnetic declination α at the same time.

Generate multiple Rockwell, Rockwell surface and Brinell hardness test force levels; Dolphin-nosed indenter measuring arm design is convenient for inner and outer contact; real-time electronic force measurement control ensures high-precision load, effectively avoiding test force overload.

Qualitative, semi-quantitative and quantitative analysis of major, trace and trace elements in samples. Based on the solid detector, it consists of a sampling system, a high-frequency generator, a plasma torch, an optical path system, a detector, analysis software and a computer system. The computer controls the instrument to monitor the instrument and automatically adjust the parameters.

It is composed of high-precision Hall probe, multi-dimensional numerical control micro-motion platform and controller, high-resolution electric rotating table and control acquisition drawing software, which can test the characteristics of static and dynamic magnetic field distribution of the product, and draw various images.

Fully automated visual inspection can inspect 100% of the products, with high inspection accuracy and fast efficiency, which can meet the inspection needs of mass production.

ISO 9001

IATF 16949

EN 9100

ISO 14001

ISO 45001

Contact(Email)